Post by sc397 on Feb 2, 2017 5:36:30 GMT -8

www.planethoustonamx.com/main/amc_flywheels.htm

Eddy's site gives a pretty good explination and part numbers of the various flywheels but, I thought I might show a little more information in this post.

6cyl and 290

001 by Rick Jones, on Flickr

001 by Rick Jones, on Flickr

290 & 343: No counter weight lug, indexes on the 4.500 out side diameter of the crank shaft flange. The only difference is AMC drilled lightening holes to balance each engine to it reciprocating assembly.

867 by Rick Jones, on Flickr

867 by Rick Jones, on Flickr

290242390 by Rick Jones, on Flickr

290242390 by Rick Jones, on Flickr

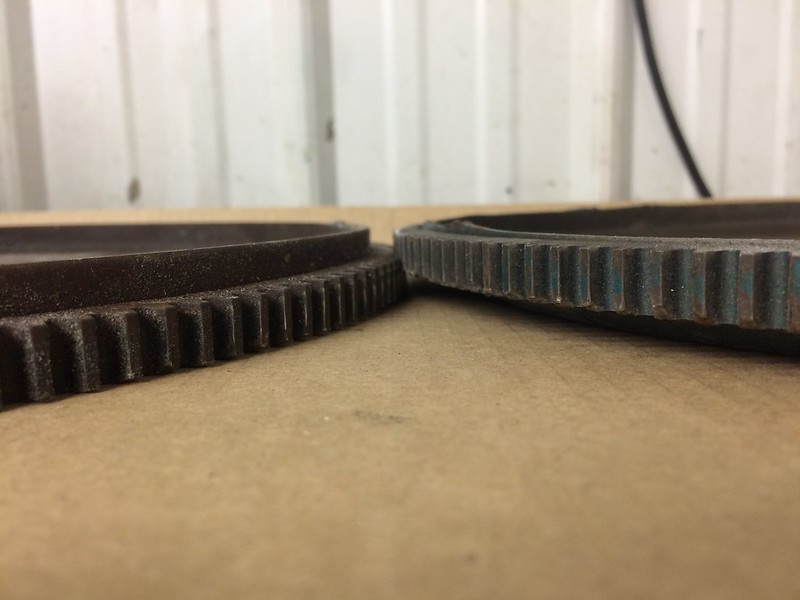

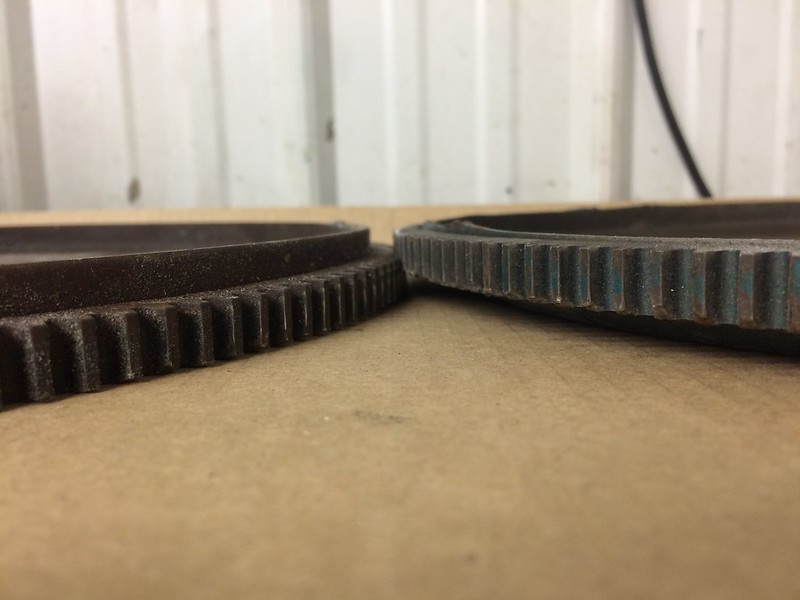

304 & 360 1970-1971: Generally speaking... counter weight is 1/2 as deep as what is found on a 390-401 flywheel, indexes on the 4.500 outside diameter of the crank shaft flange. The only difference between the 304 and 360 flywheel is AMC drilled lightening holes to balance each engine to it reciprocating assembly. I believe the 360 flywheel shown (right)in the picture is a after market part due to the machined counterweight.

304360401 by Rick Jones, on Flickr

304360401 by Rick Jones, on Flickr

IMG_1145 by Rick Jones, on Flickr

IMG_1145 by Rick Jones, on Flickr

IMG_1153 by Rick Jones, on Flickr

IMG_1153 by Rick Jones, on Flickr

304 & 360 1972 and later: : Generally speaking... counterweight is 1/2 as deep as what is found on a 390-401 flywheel, indexes on the 2.500 raised flange on the crank shaft. The only difference between the 304 and 360 flywheel is AMC drilled lightening holes to balance each engine to it reciprocating assembly.

304 1979+?: The bottom picture (above) shows a 1979 304 factory flywheel which is basically a 6cyl flywheel balanced to the 304. Notice the 3/4" lightening opposite side of where the balancing lug would normally go.

390 & 401 1969-1971: Generally speaking... counterweight is full depth of the flywheel, indexes on the 4.500 outside diameter of the crank shaft flange. The only difference between the 390 and 401 flywheel is AMC drilled lightening holes to balance each engine to it reciprocating assembly.

401 1972 and later: Generally speaking... counter wight is full depth of the flywheel, indexes on the 2.500 raised flange on the crank shaft.

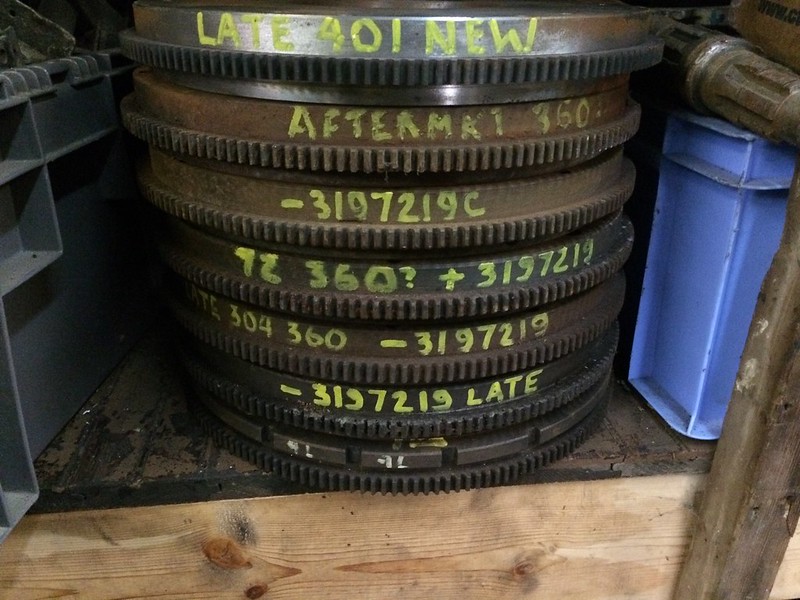

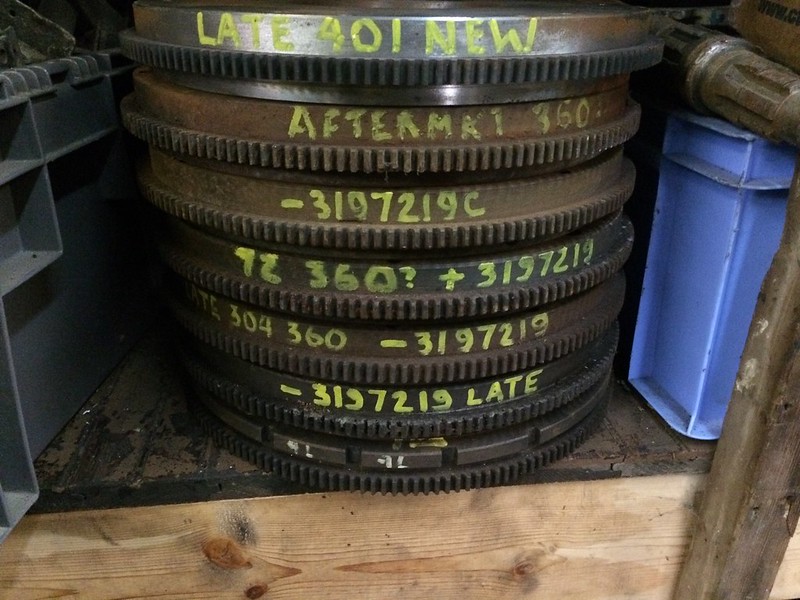

Exceptions: The 3197219 part number is stamped in nearly every configuration of flywheel so, going by part numbers is confusing. The pictures show many flywheels with the same part number but, the + indicates the full lug and the - indicates the half lug. To be even more confusing, the 319729 part number appears on both the flywheels that index on the crank flange as well as the crank shaft index ring. In addition, some early 360 flywheels may have had the full blancing lug like the 390's and 401's.

IMG_2161 by Rick Jones, on Flickr

IMG_2161 by Rick Jones, on Flickr

flywheel2_zpsz4mdajs3 by Rick Jones, on Flickr

flywheel2_zpsz4mdajs3 by Rick Jones, on Flickr

1966-1971 Flywheel counter bore to mount up to the flywheel is a slight press fit at about 4.496"

IMG_1593 by Rick Jones, on Flickr

IMG_1593 by Rick Jones, on Flickr

1972 and later flywheels have a 4.575" counter bore but indexes off of the raised flange.

IMG_1592 by Rick Jones, on Flickr

IMG_1592 by Rick Jones, on Flickr

IMG_3113 by Rick Jones, on Flickr

IMG_3113 by Rick Jones, on Flickr

FLEX PLATES:

290 and 343 1966 through 1969. Flex plates to mate up with the Borg Warner M11. No counter weights. Holes were drilled to balance. Note that they pilot off of the pilot bushing that is used on with stick cars.

The 290 flex plate is rare - only used behind a 4 barrel engine and only in '68-'69 AMX's.

003 by Rick Jones, on Flickr

003 by Rick Jones, on Flickr

360 and 390 1969-1971. Flex plates used with the Borg Warner M11 & M12. I don't have a 1971 401 flex plate but I assume it would have the same counter weight as the 390 if not slightly bigger.

102_7345 by Rick Jones, on Flickr

102_7345 by Rick Jones, on Flickr

258, 304, 360, 401 1972-1987. Flex Plates used with the 904 & 727 Transmissions.

904727flexplate by Rick Jones, on Flickr

904727flexplate by Rick Jones, on Flickr

This is a second style flex plate 304 which actually may be the first style. this is from a 1972 304. It has a curved weight rather than a rectangular one.

IMG_2897 by Rick Jones, on Flickr

IMG_2897 by Rick Jones, on Flickr

In 1988 Jeep changed the starter to a high torque type and with that, they changed the flex plate.

1988-1991 AMCJeep 360/727 Flex Plate.The one on the left is the 1988 to 1991 version and the one on the right is the 1972 to 1987 version.

IMG_2559 by Rick Jones, on Flickr

IMG_2559 by Rick Jones, on Flickr

It's a Jeep thing..

360 1972-1973. Flex plate (Right Side) used with the Nailhead TH400. Notice the full flange around the center. The front to rear off-set is different than the late TH400 as well. 1965-1973 Nailhead TH400: The Buick 350 V8, 225 V6, and AMC 327, 304, 360, 401 V8 engines used a Nailhead pattern TH400 (also known as unipattern as it was used by many other manufacturers such as Rolls Royce and Jaguar with an adapter ring) during the mid to late-1960s. The AMC engines used the TH400 with an adapter until late 1973.

1974-1979 TH400: AMC bought a TH400 case with the AMC pattern already cast. The TH400 AMC case was used until the end of 1979 model production. It uses the standard AMC engine bolt pattern.

TH400FP by Rick Jones, on Flickr

TH400FP by Rick Jones, on Flickr

Crank adapter - Will work with either flat crankshafts or flanged ones.

Adapter by Rick Jones, on Flickr

Adapter by Rick Jones, on Flickr

adapter1 by Rick Jones, on Flickr

adapter1 by Rick Jones, on Flickr

Shown with the cast iron adapter ring.

Nailhead by Rick Jones, on Flickr

Nailhead by Rick Jones, on Flickr

360 & 401 1974 and later. Flex Plate used with the TH400 AMC pattern. This is a different Flex Plate than used with the Nailhead version. Jeep did use a TH400 behind a 304 but the passenger cars did not.

732 by Rick Jones, on Flickr

732 by Rick Jones, on Flickr

This is the pilot sleeve needed for the TH400 torque converter. Engines that were mated up to a 727 won't have the sleeve. In other words, if going from a 727 to a TH400 you need to put the sleeve in. If you are swapping from a TH400 to a 727 you need o take the sleeve out. Better to know this before you bolt the transmission up. NEJoe was kind enough to machine a stock pile of these up for me. Let me know if anyone needs one.

IMG_2013 by Rick Jones, on Flickr

IMG_2013 by Rick Jones, on Flickr

This is the adapter kit to convert a early engine (1966-1971) to use the later transmissions. It actually spaces the transmission and torque converter back 1/4". No issue with the starter because it attaches to the bell housing. Here is the source for the kit: www.amclives.com/products/flexplate-adapter-kit-borg-warner-to-torqueflite-1966-71-amc

IMG_4014 by Rick Jones, on Flickr

IMG_4014 by Rick Jones, on Flickr

This is how I converted a SFI certified flex plate to accept the stock Jeep TH400 torque converter.

I removed the 401 counterweight, moved it all the way out and welded it back on. I use the 401 flex plate because of the curved weight and because it is easier for the machinist to remove metal when balancing rather than add it. I could have welded the weight on the front of the flex plate but it would have been too close to the engine plate. I also measured the difference relative from the crank shaft to the mounting surface on the flex plates where the torque converter mounts. The difference is .081". To make up the difference I welded (3) .080" thick washers to shim it to the right position.

IMG_6674 by Rick Jones, on Flickr

IMG_6674 by Rick Jones, on Flickr

Plenty of clearance now.

IMG_6673 by Rick Jones, on Flickr

IMG_6673 by Rick Jones, on Flickr

Eddy's site gives a pretty good explination and part numbers of the various flywheels but, I thought I might show a little more information in this post.

6cyl and 290

001 by Rick Jones, on Flickr

001 by Rick Jones, on Flickr290 & 343: No counter weight lug, indexes on the 4.500 out side diameter of the crank shaft flange. The only difference is AMC drilled lightening holes to balance each engine to it reciprocating assembly.

867 by Rick Jones, on Flickr

867 by Rick Jones, on Flickr 290242390 by Rick Jones, on Flickr

290242390 by Rick Jones, on Flickr304 & 360 1970-1971: Generally speaking... counter weight is 1/2 as deep as what is found on a 390-401 flywheel, indexes on the 4.500 outside diameter of the crank shaft flange. The only difference between the 304 and 360 flywheel is AMC drilled lightening holes to balance each engine to it reciprocating assembly. I believe the 360 flywheel shown (right)in the picture is a after market part due to the machined counterweight.

304360401 by Rick Jones, on Flickr

304360401 by Rick Jones, on Flickr IMG_1145 by Rick Jones, on Flickr

IMG_1145 by Rick Jones, on Flickr IMG_1153 by Rick Jones, on Flickr

IMG_1153 by Rick Jones, on Flickr304 & 360 1972 and later: : Generally speaking... counterweight is 1/2 as deep as what is found on a 390-401 flywheel, indexes on the 2.500 raised flange on the crank shaft. The only difference between the 304 and 360 flywheel is AMC drilled lightening holes to balance each engine to it reciprocating assembly.

304 1979+?: The bottom picture (above) shows a 1979 304 factory flywheel which is basically a 6cyl flywheel balanced to the 304. Notice the 3/4" lightening opposite side of where the balancing lug would normally go.

390 & 401 1969-1971: Generally speaking... counterweight is full depth of the flywheel, indexes on the 4.500 outside diameter of the crank shaft flange. The only difference between the 390 and 401 flywheel is AMC drilled lightening holes to balance each engine to it reciprocating assembly.

401 1972 and later: Generally speaking... counter wight is full depth of the flywheel, indexes on the 2.500 raised flange on the crank shaft.

Exceptions: The 3197219 part number is stamped in nearly every configuration of flywheel so, going by part numbers is confusing. The pictures show many flywheels with the same part number but, the + indicates the full lug and the - indicates the half lug. To be even more confusing, the 319729 part number appears on both the flywheels that index on the crank flange as well as the crank shaft index ring. In addition, some early 360 flywheels may have had the full blancing lug like the 390's and 401's.

IMG_2161 by Rick Jones, on Flickr

IMG_2161 by Rick Jones, on Flickr flywheel2_zpsz4mdajs3 by Rick Jones, on Flickr

flywheel2_zpsz4mdajs3 by Rick Jones, on Flickr1966-1971 Flywheel counter bore to mount up to the flywheel is a slight press fit at about 4.496"

IMG_1593 by Rick Jones, on Flickr

IMG_1593 by Rick Jones, on Flickr1972 and later flywheels have a 4.575" counter bore but indexes off of the raised flange.

IMG_1592 by Rick Jones, on Flickr

IMG_1592 by Rick Jones, on Flickr IMG_3113 by Rick Jones, on Flickr

IMG_3113 by Rick Jones, on FlickrFLEX PLATES:

290 and 343 1966 through 1969. Flex plates to mate up with the Borg Warner M11. No counter weights. Holes were drilled to balance. Note that they pilot off of the pilot bushing that is used on with stick cars.

The 290 flex plate is rare - only used behind a 4 barrel engine and only in '68-'69 AMX's.

003 by Rick Jones, on Flickr

003 by Rick Jones, on Flickr360 and 390 1969-1971. Flex plates used with the Borg Warner M11 & M12. I don't have a 1971 401 flex plate but I assume it would have the same counter weight as the 390 if not slightly bigger.

102_7345 by Rick Jones, on Flickr

102_7345 by Rick Jones, on Flickr 258, 304, 360, 401 1972-1987. Flex Plates used with the 904 & 727 Transmissions.

904727flexplate by Rick Jones, on Flickr

904727flexplate by Rick Jones, on FlickrThis is a second style flex plate 304 which actually may be the first style. this is from a 1972 304. It has a curved weight rather than a rectangular one.

IMG_2897 by Rick Jones, on Flickr

IMG_2897 by Rick Jones, on FlickrIn 1988 Jeep changed the starter to a high torque type and with that, they changed the flex plate.

1988-1991 AMCJeep 360/727 Flex Plate.The one on the left is the 1988 to 1991 version and the one on the right is the 1972 to 1987 version.

IMG_2559 by Rick Jones, on Flickr

IMG_2559 by Rick Jones, on FlickrIt's a Jeep thing..

360 1972-1973. Flex plate (Right Side) used with the Nailhead TH400. Notice the full flange around the center. The front to rear off-set is different than the late TH400 as well. 1965-1973 Nailhead TH400: The Buick 350 V8, 225 V6, and AMC 327, 304, 360, 401 V8 engines used a Nailhead pattern TH400 (also known as unipattern as it was used by many other manufacturers such as Rolls Royce and Jaguar with an adapter ring) during the mid to late-1960s. The AMC engines used the TH400 with an adapter until late 1973.

1974-1979 TH400: AMC bought a TH400 case with the AMC pattern already cast. The TH400 AMC case was used until the end of 1979 model production. It uses the standard AMC engine bolt pattern.

TH400FP by Rick Jones, on Flickr

TH400FP by Rick Jones, on FlickrCrank adapter - Will work with either flat crankshafts or flanged ones.

Adapter by Rick Jones, on Flickr

Adapter by Rick Jones, on Flickr adapter1 by Rick Jones, on Flickr

adapter1 by Rick Jones, on FlickrShown with the cast iron adapter ring.

Nailhead by Rick Jones, on Flickr

Nailhead by Rick Jones, on Flickr360 & 401 1974 and later. Flex Plate used with the TH400 AMC pattern. This is a different Flex Plate than used with the Nailhead version. Jeep did use a TH400 behind a 304 but the passenger cars did not.

732 by Rick Jones, on Flickr

732 by Rick Jones, on FlickrThis is the pilot sleeve needed for the TH400 torque converter. Engines that were mated up to a 727 won't have the sleeve. In other words, if going from a 727 to a TH400 you need to put the sleeve in. If you are swapping from a TH400 to a 727 you need o take the sleeve out. Better to know this before you bolt the transmission up. NEJoe was kind enough to machine a stock pile of these up for me. Let me know if anyone needs one.

IMG_2013 by Rick Jones, on Flickr

IMG_2013 by Rick Jones, on FlickrThis is the adapter kit to convert a early engine (1966-1971) to use the later transmissions. It actually spaces the transmission and torque converter back 1/4". No issue with the starter because it attaches to the bell housing. Here is the source for the kit: www.amclives.com/products/flexplate-adapter-kit-borg-warner-to-torqueflite-1966-71-amc

IMG_4014 by Rick Jones, on Flickr

IMG_4014 by Rick Jones, on FlickrThis is how I converted a SFI certified flex plate to accept the stock Jeep TH400 torque converter.

I removed the 401 counterweight, moved it all the way out and welded it back on. I use the 401 flex plate because of the curved weight and because it is easier for the machinist to remove metal when balancing rather than add it. I could have welded the weight on the front of the flex plate but it would have been too close to the engine plate. I also measured the difference relative from the crank shaft to the mounting surface on the flex plates where the torque converter mounts. The difference is .081". To make up the difference I welded (3) .080" thick washers to shim it to the right position.

IMG_6674 by Rick Jones, on Flickr

IMG_6674 by Rick Jones, on FlickrPlenty of clearance now.

IMG_6673 by Rick Jones, on Flickr

IMG_6673 by Rick Jones, on Flickr